TPS856 Ver la hoja de datos (PDF) - Toshiba

Número de pieza

componentes Descripción

Fabricante

TPS856 Datasheet PDF : 13 Pages

| |||

TPS856

Handling Precautions

Insert a bypass condenser of up to 0.1μF between VCC and GND near the device to stabilize the power supply line.

Please put the bypass capacitor of 0.1uF between OUT and GND near the device if you use it as a current output

(There is no load resistance).

When VCC is turned on it takes at least 20 ms for the internal circuit to stabilize. During this time the output

signal is unstable. Please do not use the unstable signal as the output signal.

Moisture-Proof Packing

(1) To avoid moisture absorption by the resin, the product is packed in an aluminum envelope with silica

gel.

(2) Since the optical characteristics of the device can be affected during soldering by vaporization

resulting from prior absorption of moisture and they should therefore be stored under the following

conditions:

Temperature: 5°C to 30°C, Relative humidity: 70% (max), Time: 168 h (max)

(3) Baking in taping with reel is required if the devices have been store unopened for more than six

months or if the aluminum envelope has been opened for more than 168 h.

These devices are packed on tapes; hence, please avoid baking at high temperature.

Recommended baking conditions: 60°C for 12 h or longer, Perform baking only once

Mounting Precautions

TPS856 uses a clear resin, and delicate handling is necessary for it.

The characteristic change or the product might be damaged by the handling method of mounting.

Please note the following and handle the product.

(1) Do not apply stress to the resin at high temperature.

Time until the product returns at the normal temperature after mounting of

the reflow is different according to the mounting substrate and the environment.

Please do not give the stress with heat remained in the product.

(2) The resin part is easily scratched, so avoid friction with hard materials.

(3) When installing the assembly board in equipment, ensure that this product does not come into

contact with other components.

(4) Please confirm the heat contraction of the substrate of the reflow mounting doesn't influence the

product. The load is given to the product by mounting that the heat contraction is large on the

substrate and the installation position of the substrate. Please note that the characteristic changes

or the product might be damaged.

Mounting Methods

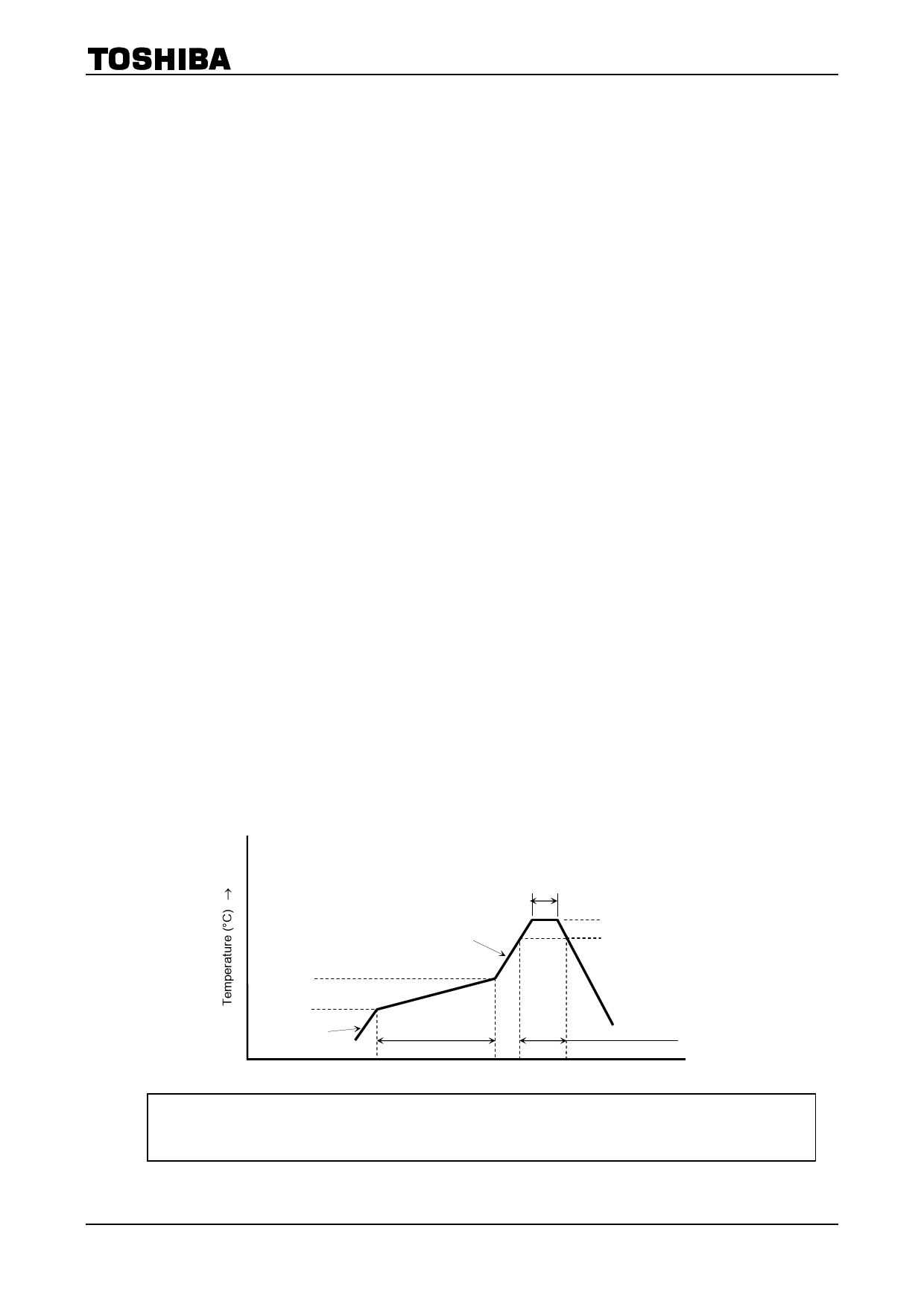

(1) Example of reflow soldering

190°C

180°C

4°C/s max (*)

4°C/s max (*)

10s max (*)

260°C max (*)

230°C

Preheating part

60∼120 s

30 s to 50 s Heating part

Time (s) →

(*)The product is evaluated using above reflow soldering conditions. No additional test is performed

exceed the condition (i.e. the condition more than MAX values) as an evaluation.

Please perform reflow soldering under the above conditions. Perform reflow soldering no more than

twice.

• Please perform the first reflow soldering within 168 h after opening the package with reference to

the above temperature profile.

5

2007-10-01