ARA200A09 Ver la hoja de datos (PDF) - Matsushita Electric Works

Número de pieza

componentes Descripción

Fabricante

ARA200A09 Datasheet PDF : 3 Pages

| |||

RA

REFERENCE DATA

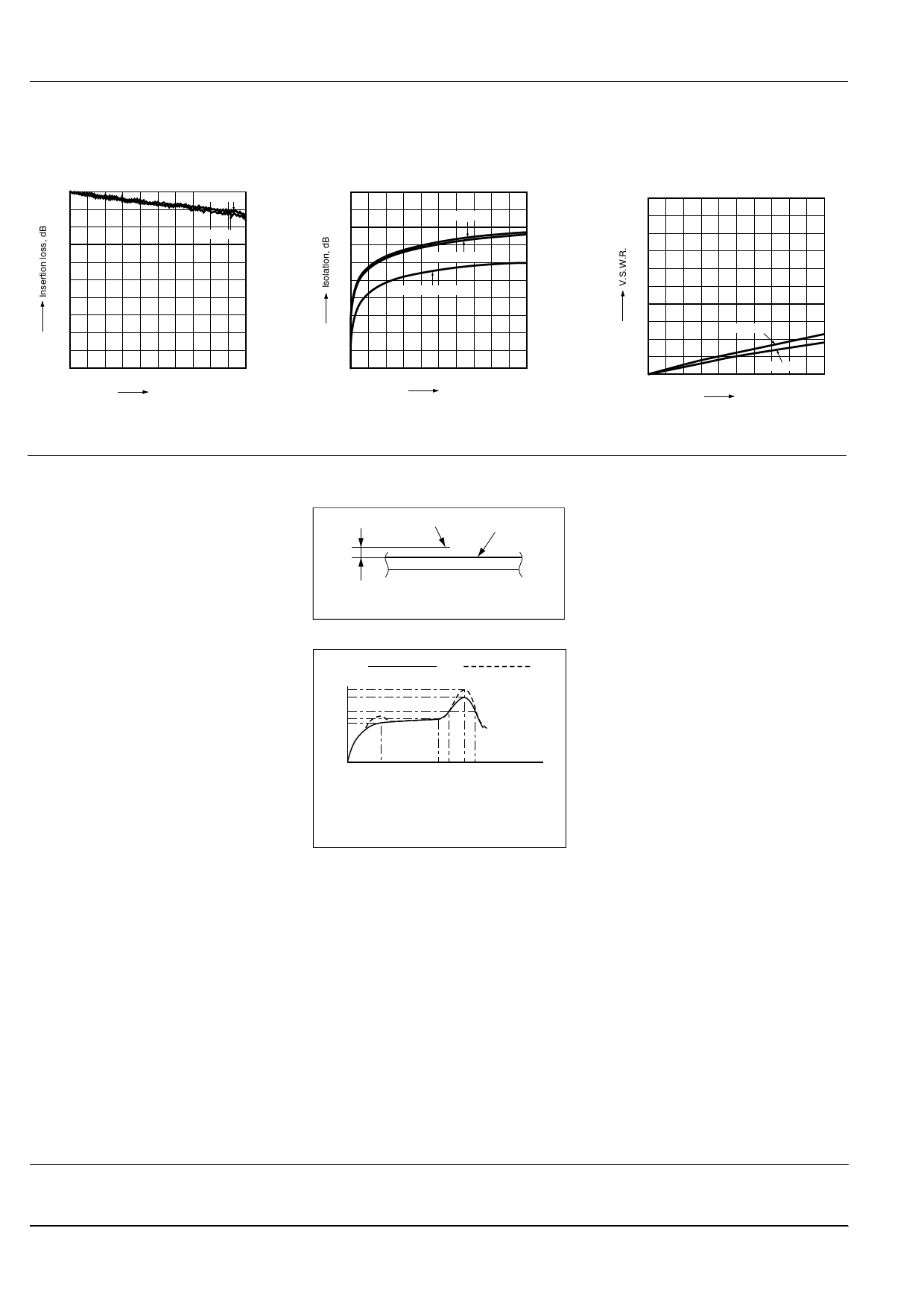

1. High frequency characteristics

Sample: ARA200A12

Measuring method: Measured with HP network analyzer (HP8753C).

• Insertion loss

0

COM-NO

• Isolation

0

0.2

20

COM-NC

0.3

30

0.4

40

0.6

60

COM-NC

COM-NO

CONTACT sets

0.8

80

1.0

300kHz

0.5GHz

Frequency

1.0GHz

100

300kHz

0.5GHz

Frequency

1.0GHz

• V.S.W.R.

1.5

1.4

1.3

1.2

1.1

1.0

300kHz

COM-NC

COM-NO

0.5GHz

Frequency

1.0GHz

NOTES

1. Coil operating power

Pure DC current should be applied to the

coil. The wave form should be rectangu-

lar. If it includes ripple, the ripple factor

should be less than 5%.

However, check it with the actual circuit

since the characteristics may be slightly

different. The nominal operating voltage

should be applied to the coil for more

than 10 ms to set/reset the latching type

relay.

2. Coil connection

When connecting coils, refer to the wiring

diagram to prevent mis-operation or mal-

function.

3. External magnetic field

Since RA relays are highly sensitive po-

larized relays, their characteristics will be

affected by a strong external magnetic

field. Avoid using the relay under that

condition.

4. Cleaning

For automatic cleaning, the boiling meth-

od is recommended. Avoid ultrasonic

cleaning which subjects the relays to high

frequency vibrations, which may cause

the contacts to stick.

It is recommended that alcoholic solvents

be used.

5. Soldering

Manual soldering shall be performed un-

der following condition.

Tip temperature: 280°C to 300°C .536°F

to 572°F

Wattage: 30 to 60W

Soldering time: within 5s

In case of automatic soldering, the follow-

ing conditions should be observed

1) Position of measuring temperature

1.0mm .039inch B

A

A: Surface of PC board where relay is mounted.

B: Above the PC board surface.

2) IR (infrared reflow) soldering method

A:

B:

T5

T4

T3

T2

T1

t1

T1=150°C 302°F

T2=160°C 320°F

T3=183°C 361°F

T4=245°C 473°F

T5=270°C 518°F

t2 t3 t4 t5

t2 - t1 = 80 to 120 s

t5 - t3 = 30 to 40 s

t4 = 170 to 190 s

Temperature rise of relay itself may vary

according to the mounting level or the

heating method of reflow equipment.

Therefore, please set the temperature of

soldering portion of relay terminal and

the top surface of the relay case not to

exceed the above mentioned soldering

condition.

It is recommended to check the tempera-

ture rise of each portion under actual

mounting condition before use.

The soldering earth shall be performed

by manual soldering.

For Cautions for Use, see Relay Technical Information (Page 48 to 76).

98/21/2000

All Rights Reserved, © Copyright Matsushita Electric Works, Ltd.

Go To Online Catalog