LT1677CS8 Ver la hoja de datos (PDF) - Linear Technology

Número de pieza

componentes Descripción

Fabricante

LT1677CS8 Datasheet PDF : 16 Pages

| |||

LT1677

APPLICATIO S I FOR ATIO

Offset Voltage and Drift

Thermocouple effects, caused by temperature gradients

across dissimilar metals at the contacts to the input

terminals, can exceed the inherent drift of the amplifier

unless proper care is exercised. Air currents should be

minimized, package leads should be short, the two input

leads should be close together and maintained at the same

temperature.

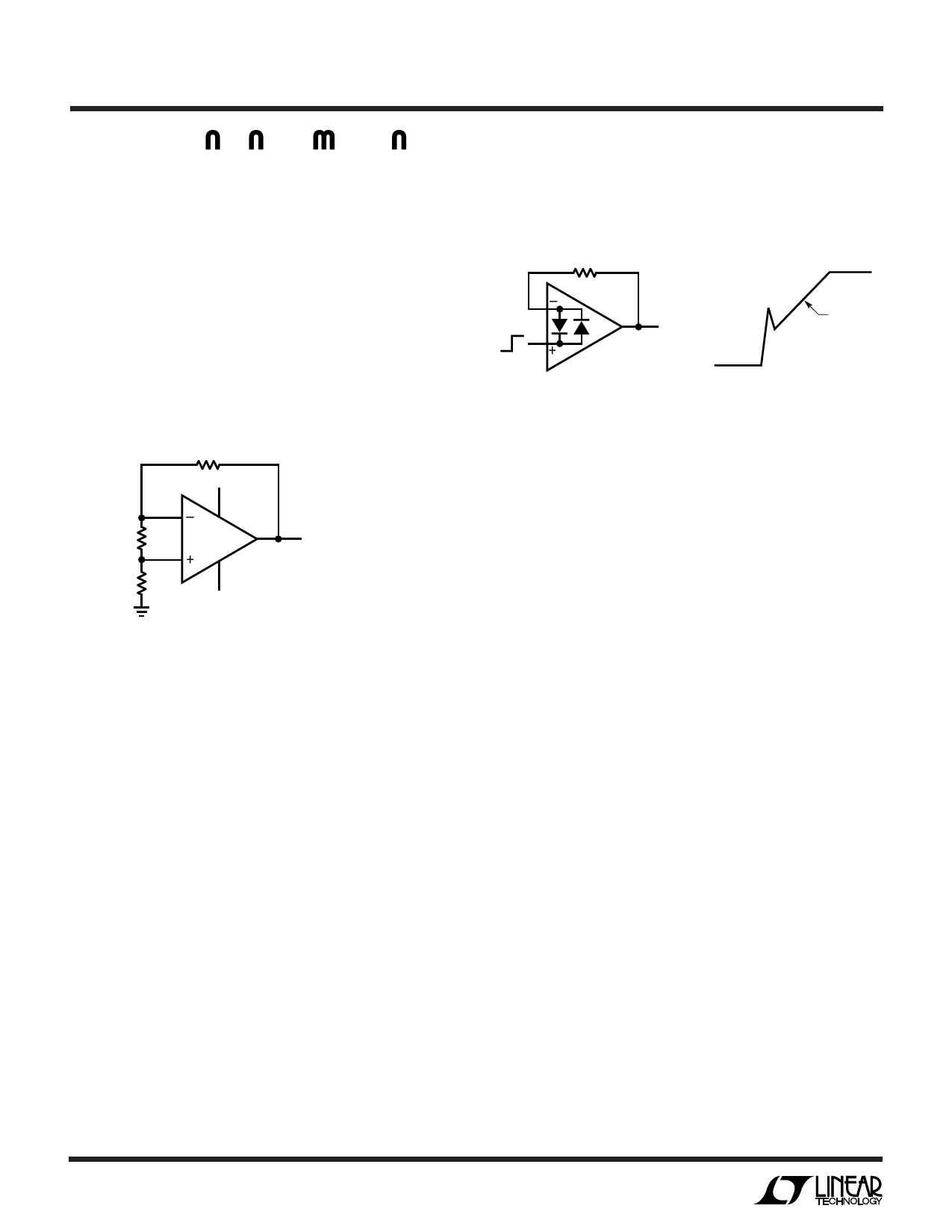

The circuit shown to measure offset voltage is also used

as the burn-in configuration for the LT1677, with the

supply voltages increased to ±20V (Figure 4).

creating additional phase shift and reducing the phase

margin. A small capacitor (20pF to 50pF) in parallel with RF

will eliminate this problem.

RF

–

+

LT1677

OUTPUT

Figure 5. Pulsed Operation

2.5V/µs

1677 F05

50k*

15V

2–

7

100Ω* LT1677

3+

4

50k*

–15V

6

VOUT

VOUT = 1000VOS

*RESISTORS MUST HAVE LOW

THERMOELECTRIC POTENTIAL

1677 F04

Figure 4. Test Circuit for Offset Voltage and

Offset Voltage Drift with Temperature

Unity-Gain Buffer Application

When RF ≤ 100Ω and the input is driven with a fast, large-

signal pulse (>1V), the output waveform will look as

shown in the pulsed operation diagram (Figure 5).

During the fast feedthrough-like portion of the output, the

input protection diodes effectively short the output to the

input and a current, limited only by the output short-circuit

protection, will be drawn by the signal generator. With

RF ≥ 500Ω, the output is capable of handling the current

requirements (IL ≤ 20mA at 10V) and the amplifier stays

in its active mode and a smooth transition will occur.

As with all operational amplifiers when RF > 2k, a pole will

be created with RF and the amplifier’s input capacitance,

Noise Testing

The 0.1Hz to 10Hz peak-to-peak noise of the LT1677 is

measured in the test circuit shown (Figure 6a). The fre-

quency response of this noise tester (Figure 6b) indicates

that the 0.1Hz corner is defined by only one zero. The test

time to measure 0.1Hz to 10Hz noise should not exceed

ten seconds, as this time limit acts as an additional zero to

eliminate noise contributions from the frequency band

below 0.1Hz.

Measuring the typical 70nV peak-to-peak noise perfor-

mance of the LT1677 requires special test precautions:

1. The device should be warmed up for at least five

minutes. As the op amp warms up, its offset voltage

changes typically 3µV due to its chip temperature

increasing 10°C to 20°C from the moment the power

supplies are turned on. In the ten-second measurement

interval these temperature-induced effects can easily

exceed tens of nanovolts.

2. For similar reasons, the device must be well shielded

from air currents to eliminate the possibility of

thermoelectric effects in excess of a few nanovolts,

which would invalidate the measurements.

3. Sudden motion in the vicinity of the device can also

“feedthrough” to increase the observed noise.

10