MP02HBN175-10 Ver la hoja de datos (PDF) - Dynex Semiconductor

Número de pieza

componentes Descripción

Fabricante

MP02HBN175-10 Datasheet PDF : 8 Pages

| |||

MP02X175 Series

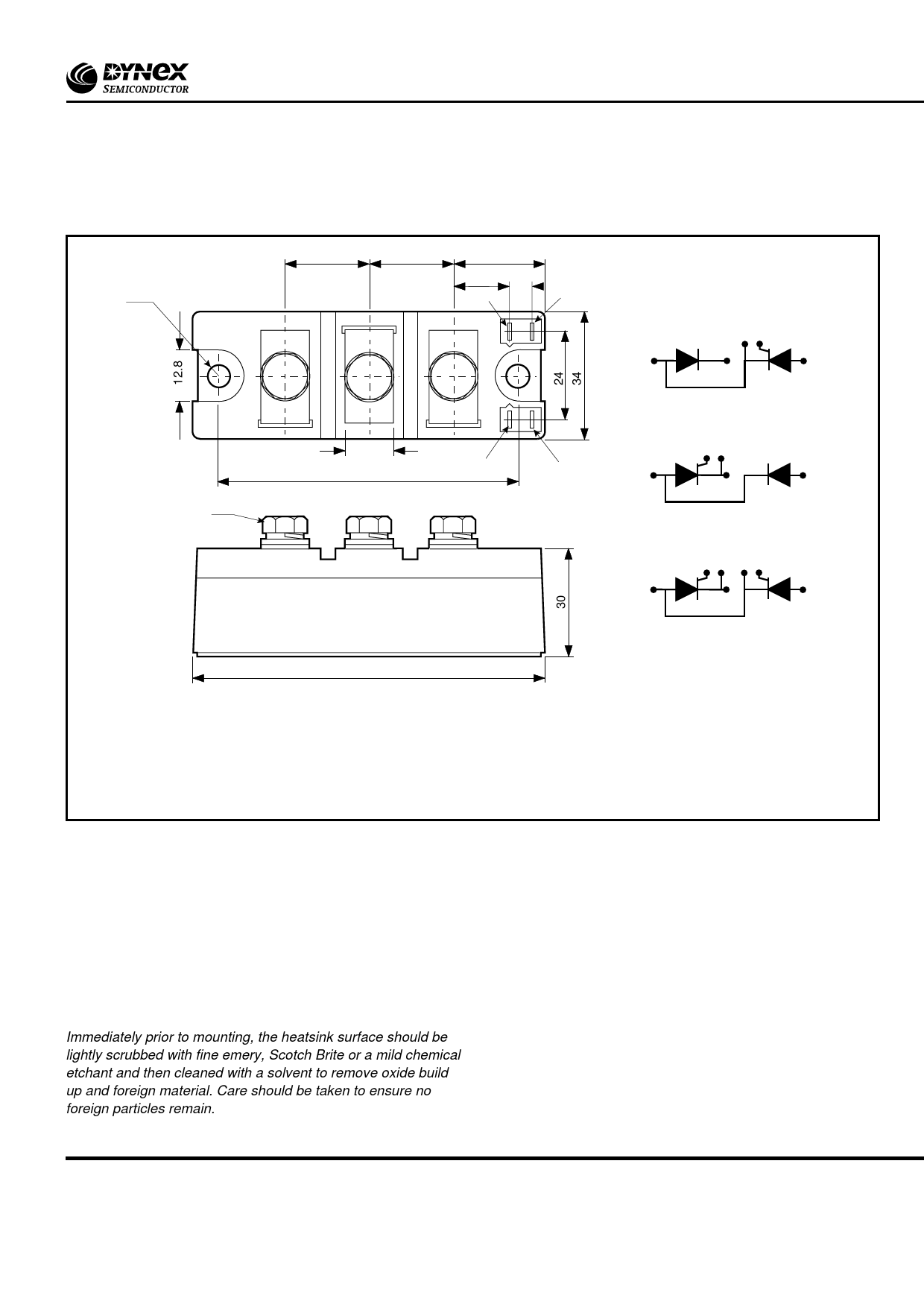

PACKAGE DETAILS

For further package information, please visit our website or contact your nearest Customer Service Centre. All dimensions in mm, unless

stated otherwise. DO NOT SCALE.

2 holes Ø6.5

23

23

24

15

5

K2

G2

1

K2 G2

2

3

Circuit type: HBN

13

G1 K1

80

K1

G1

1

2

3

3x M6

1

2

3

Circuit type: HBP

G1 K1 K2 G2

1

2

3

Circuit type: HBT

94

Nominal weight: 350g

Recommended fixings for mounting: M6 socket head cap screws

Recommended mounting torque: 6Nm (55lb.ins)

Recommended torque for electrical connections: 5Nm (44lb.ins)

Maximum torque for electrical connections: 8Nm (70lb.ins)

Module outline type code: MP02

MOUNTING RECOMMENDATIONS

Adequate heatsinking is required to maintain the base

temperature at 75˚C if full rated current is to be achieved. Power

dissipation may be calculated by use of VT(TO) and rT information

in accordance with standard formulae. We can provide

assistance with calculations or choice of heatsink if required.

The heatsink surface must be smooth and flat; a surface finish

of N6 (32µin) and a flatness within 0.05mm (0.002") are

recommended.

Immediately prior to mounting, the heatsink surface should be

lightly scrubbed with fine emery, Scotch Brite or a mild chemical

etchant and then cleaned with a solvent to remove oxide build

up and foreign material. Care should be taken to ensure no

foreign particles remain.

An even coating of thermal compound (eg. Unial) should be

applied to both the heatsink and module mounting surfaces.

This should ideally be 0.05mm (0.002") per surface to ensure

optimum thermal performance.

After application of thermal compound, place the module

squarely over the mounting holes, (or ‘T’ slots) in the heatsink.

Fit and finger tighten the recommended fixing bolts at each end.

Using a torque wrench, continue to tighten the fixing bolts by

rotating each bolt in turn no more than 1/4 of a revolution at a

time, until the required torque of 6Nm (55lbs.ins) is reached on

all bolts at both ends.

It is not acceptable to fully tighten one fixing bolt before starting

to tighten the others. Such action may DAMAGE the module.

7/8

www.dynexsemi.com