ML4425CP Ver la hoja de datos (PDF) - Fairchild Semiconductor

Número de pieza

componentes Descripción

Fabricante

ML4425CP Datasheet PDF : 16 Pages

| |||

ML4425

PRODUCT SPECIFICATION

Back EMF Sensing PLL Commutation Control

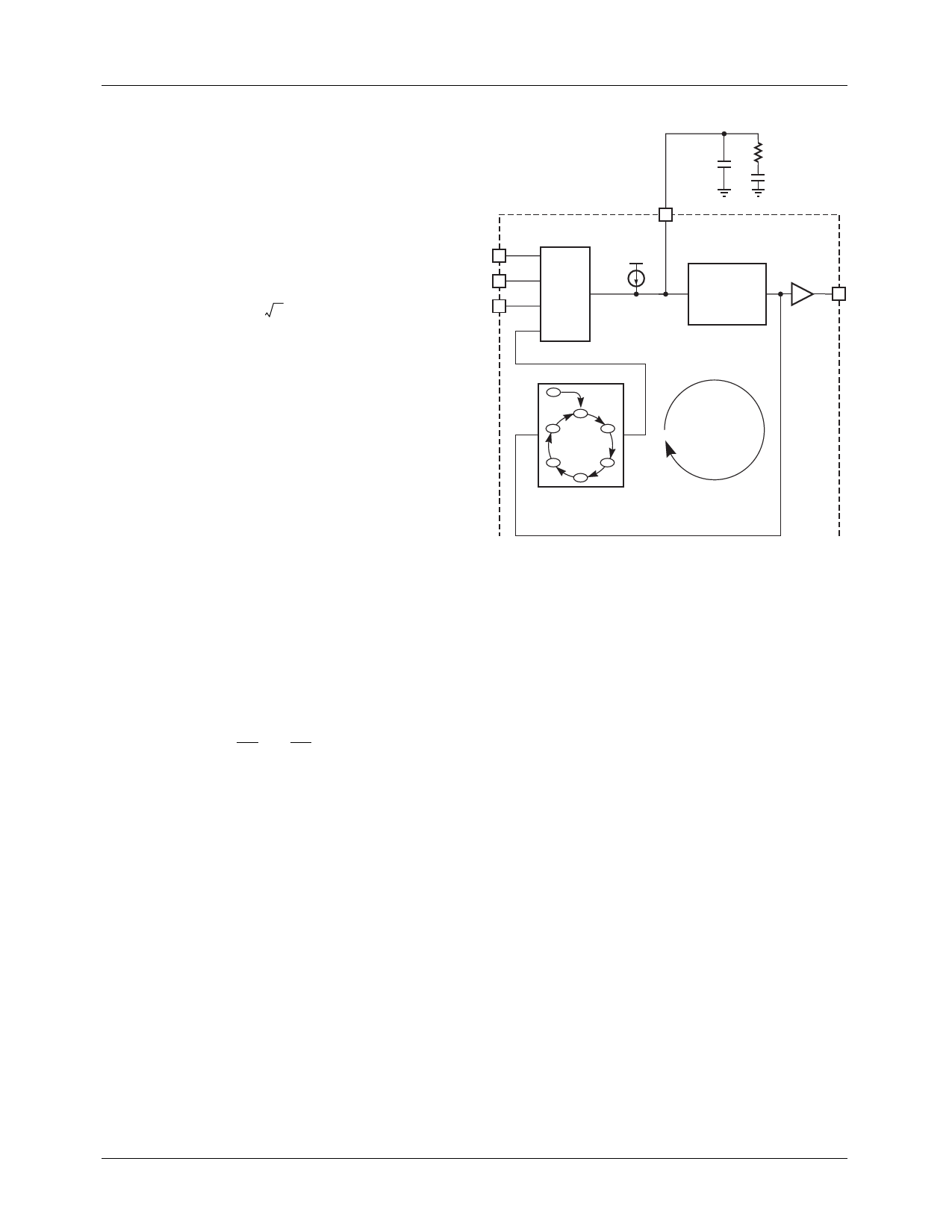

Three blocks form a phase locked loop that locks the com-

mutation clock onto the back EMF signal: the commutation

state machine, the voltage controlled oscillator, and the back

EMF sampler. The complete phase locked loop is illustrated

in Figure 7. The phased locked loop requires a lead lag filter

that is set by external components on SPEED FB. The com-

ponents are selected as follows:

CSPEEDFB1

=

0.25

×

-K----O----1-

M

×

---I--n-------1-------d0------0-----N-----S2---2×-----f--V---C----O---2--

(6a)

RSPEEDFB = 2 × M × In1----0d---0-- × N-----S-----×----K-----Of--V--1--C--×-O----(--1-----–----M------) (6b

CSPEEDFB2 = CSPEEDFB1 × (M – 1)

(6c)

Start-Up Sequence

When power is first applied to the ML4425 and the motor is

at rest, the back EMF is equal to zero. The motor needs to be

rotating for the back EMF sampler to lock onto the rotor

position and commutate the motor. The ML4425 uses an

open loop start-up technique to bring the rotor from rest up

to a speed fast enough to allow back EMF sensing. Start-up

is comprised of three modes: align mode, ramp mode, and

run mode.

Align Mode (RESET)

Before the motor can be started, the rotor must be in a known

position. When power is first applied to the ML4425, the

controller is reset into the align mode. Align mode turns on

the output drivers LB, HA, and HC which aligns the motor

into a position 30 electrical degrees before the center of the

first commutation state. This is shown as state R in the com-

mutation states of Table 1. Align mode must last long enough

to allow the motor and its load to settle into this position. The

align mode time is set by a capacitor connected to the CAT

pin as shown in Figure 8. CAT is charged by a constant

750µA current from GND to 1.5 V until the align comparator

trips to end the align mode. A starting point for CAT is calcu-

lated as follows:

CAT = t--S-----×-----7---.--5-----×1----.1--5--0-V--–---7----×-----a----m-----p--

(7)

If the align time is not long enough to allow the rotor to settle

for reliable starting, then increase CAT until the desired per-

formance is achieved.

CSPEEDFB1

RSPEEDFB

CSPEEDFB2

FB A

22

FB B

23

FB C

24

20

SPEED

FB

VDD

BACK 500nA

EMF

SAMPLER

VOLTAGE

CONTROLLED

OSCILLATOR

VCO/TACH

13

R

A

F

B

E

C

D

COMMUTATION

STATE MACHINE

PHASE

LOCKED

LOOP

Figure 7. Back EMF Commutation Phase Locked Loop

Ramp Mode

At the end of align mode the controller goes into ramp mode.

Ramp mode starts commutating through the states A through

F as shown in Table 1. This ramps up the commutation fre-

quency, and therefore the motor speed, for a fixed length of

time. This allows the motor to reach a sufficient speed for the

back EMF sampler to lock commutation onto the motor’s

back EMF. The amount of time the ML4425 stays in ramp

mode is determined by a capacitor connected to the CRT pin

as shown in Figure 8. CRT is charged by a constant 750µA

current from GND to 1.5 V until the ramp comparator trips

to end the ramp mode. This gives a fixed ramp time. CRT is

calculated as follows:

CRT = 2----π-----×-----J--I--M×-----A5---X--×---×--1--K-0----–t--7×----×-3----a-×---m--N---p-----×-----K----V--

(8)

The rate at which the ML4425 ramps up the motor speed is

determined by a fixed 500µA current source on the SPEED

FB pin. The current sources charges up the PLL filter com-

ponents causing the VCO frequency to ramp up. During

ramp mode, the back EMF sampler is disabled to allow con-

trol of the ramping to be set only by the 500µA current

source. The ramp based on the SPEED FB filter is generally

too fast for the motor to keep up, so a capacitor from CRR to

SPEED FB can be added to slow down the ramping rate. The

optimal ramp rate is based on the motor and load parameters

and is can be adjusted by varying the value of CRR.

10

REV. 1.0.2 7/2/01