TNY274PG Ver la hoja de datos (PDF) - Power Integrations, Inc

Número de pieza

componentes Descripción

Fabricante

TNY274PG Datasheet PDF : 24 Pages

| |||

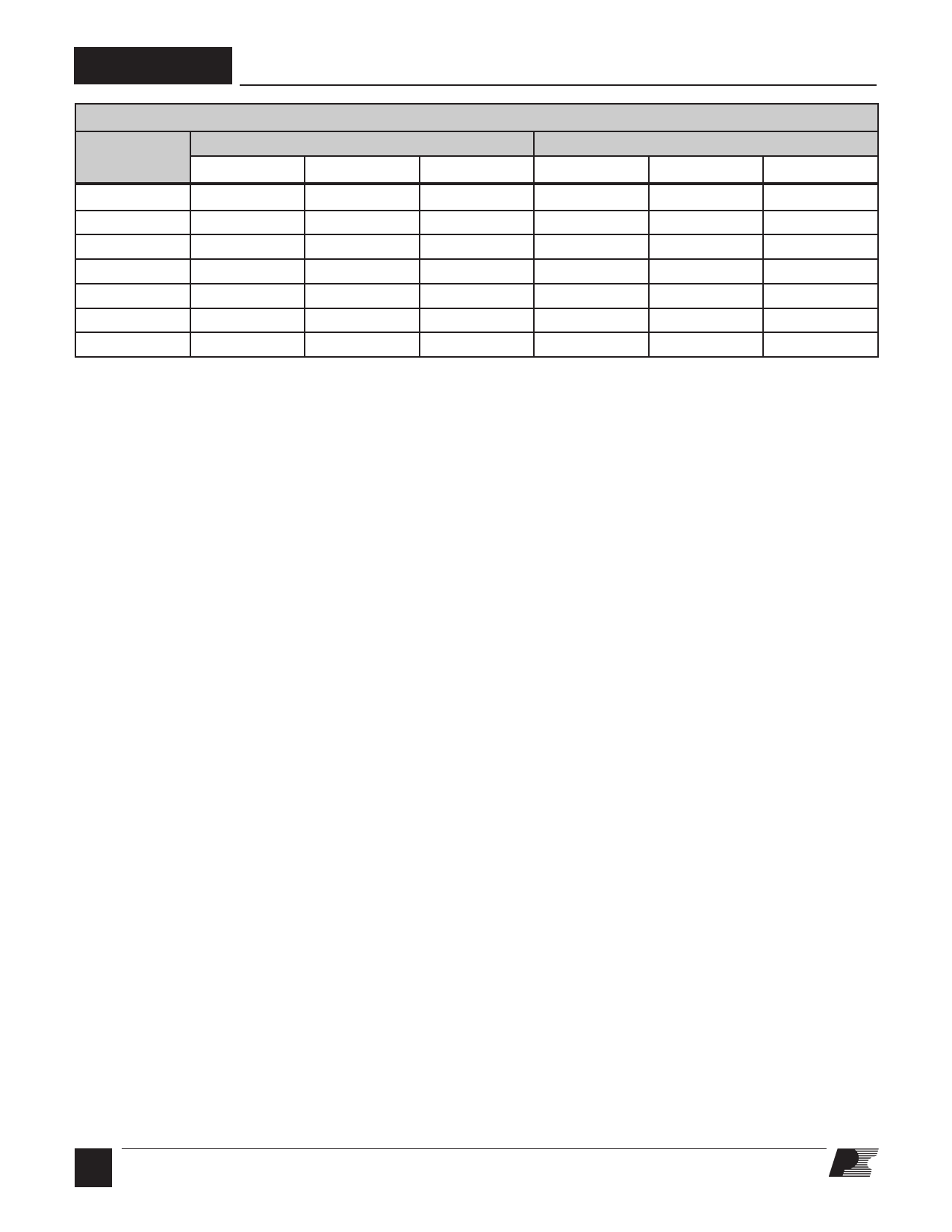

TNY274-280

PRODUCT

TNY274 P or G

TNY275 P or G

TNY276 P or G

TNY277 P or G

TNY278 P or G

TNY279 P or G

TNY280 P or G

ILIMIT-1

9

10.8

11.8

15.1

19.4

23.7

28

OUTPUT POWER TABLE

230 VAC ±15%

ILIMIT

10.9

ILIMIT+1

9.1

ILIMIT-1

7.1

12

15.1

8.4

15.3

19.4

9.2

19.6

23.7

11.8

24

28

15.1

28.4

32.2

18.5

32.7

36.6

21.8

Table 2. Minimum Practical Power at Three Selectable Current Limit Levels.

85-265 VAC

ILIMIT

8.5

9.3

11.9

15.3

18.6

22

25.4

ILIMIT+1

7.1

11.8

15.1

18.5

21.8

25.2

28.5

For best performance of the OVP function, it is recommended

that a relatively high bias winding voltage is used, in the range of

15 V-30 V. This minimizes the error voltage on the bias winding

due to leakage inductance and also ensures adequate voltage

during no-load operation from which to supply the BP/M pin

for reduced no-load consumption.

Selecting the Zener diode voltage to be approximately 6 V

above the bias winding voltage (28 V for 22 V bias winding)

gives good OVP performance for most designs, but can be

adjusted to compensate for variations in leakage inductance.

Adding additional filtering can be achieved by inserting a low

value (10 Ω to 47 Ω) resistor in series with the bias winding

diode and/or the OVP Zener as shown by R7 and R3 in

Figure 14. The resistor in series with the OVP Zener also limits

the maximum current into the BP/M pin.

Reducing No-load Consumption

As TinySwitch-III is self-powered from the BP/M pin capacitor,

there is no need for an auxillary or bias winding to be provided

on the transformer for this purpose. Typical no-load consumption

when self-powered is <150 mW at 265 VAC input. The addition

of a bias winding can reduce this down to <50 mW by supplying

the TinySwitch-III from the lower bias voltage and inhibiting the

internal high voltage current source. To achieve this, select the

value of the resistor (R8 in Figure 14) to provide the data sheet

DRAIN supply current. In practice, due to the reduction of the

bias voltage at low load, start with a value equal to 40% greater

than the data sheet maximum current, and then increase the value

of the resistor to give the lowest no-load consumption.

Audible Noise

The cycle skipping mode of operation used in TinySwitch-III

can generate audio frequency components in the transformer.

To limit this audible noise generation the transformer should

be designed such that the peak core flux density is below

3000 Gauss (300 mT). Following this guideline and using the

standard transformer production technique of dip varnishing

10 E

2/06

practically eliminates audible noise. Vacuum impregnation

of the transformer should not be used due to the high primary

capacitance and increased losses that result. Higher flux densities

are possible, however careful evaluation of the audible noise

performance should be made using production transformer

samples before approving the design.

Ceramic capacitors that use dielectrics such as Z5U, when used

in clamp circuits, may also generate audio noise. If this is the

case, try replacing them with a capacitor having a different

dielectric or construction, for example a film type.

TinySwitch-lll Layout Considerations

Layout

See Figure 15 for a recommended circuit board layout for

TinySwitch-III.

Single Point Grounding

Use a single point ground connection from the input filter capacitor

to the area of copper connected to the SOURCE pins.

Bypass Capacitor (CBP)

The BP/M pin capacitor should be located as near as possible

to the BP/M and SOURCE pins.

Primary Loop Area

The area of the primary loop that connects the input filter

capacitor, transformer primary and TinySwitch-III together

should be kept as small as possible.

Primary Clamp Circuit

A clamp is used to limit peak voltage on the DRAIN pin at turn

off. This can be achieved by using an RCD clamp or a Zener

(~200 V) and diode clamp across the primary winding. In all

cases, to minimize EMI, care should be taken to minimize the

circuit path from the clamp components to the transformer and

TinySwitch-III.