LT1944 Ver la hoja de datos (PDF) - Linear Technology

Número de pieza

componentes Descripción

Fabricante

LT1944 Datasheet PDF : 8 Pages

| |||

LT1944

APPLICATIO S I FOR ATIO

Choosing an Inductor

Several recommended inductors that work well with the

LT1944 are listed in Table 1, although there are many other

manufacturers and devices that can be used. Consult each

manufacturer for more detailed information and for their

entire selection of related parts. Many different sizes and

shapes are available. Use the equations and recommenda-

tions in the next few sections to find the correct inductance

value for your design.

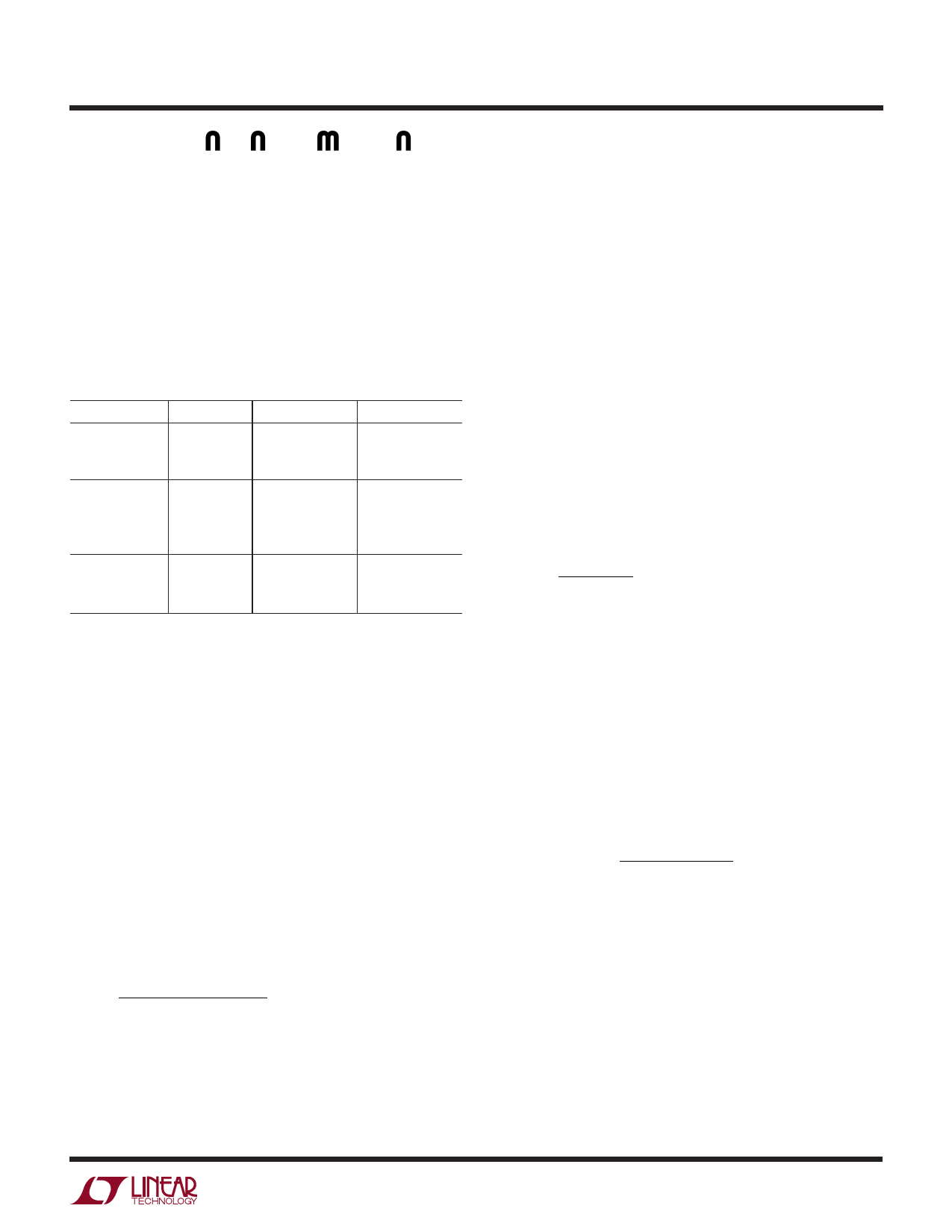

Table 1. Recommended Inductors

PART

VALUE (µH) MAX DCR (Ω)

LQH3C4R7

4.7

0.26

LQH3C100

10

0.30

LQH3C220

22

0.92

CD43-4R7

4.7

0.11

CD43-100

10

0.18

CDRH4D18-4R7

4.7

0.16

CDRH4D18-100

10

0.20

DO1608-472

4.7

0.09

DO1608-103

10

0.16

DO1608-223

22

0.37

VENDOR

Murata

(714) 852-2001

www.murata.com

Sumida

(847) 956-0666

www.sumida.com

Coilcraft

(847) 639-6400

www.coilcraft.com

voltages below 7V, a 4.7µH inductor is the best choice,

even though the equation above might specify a smaller

value. This is due to the inductor current overshoot that

occurs when very small inductor values are used (see

Current Limit Overshoot section).

For higher output voltages, the formula above will give

large inductance values. For a 2V to 20V converter (typical

LCD Bias application), a 21µH inductor is called for with

the above equation, but a 10µH inductor could be used

without excessive reduction in maximum output current.

Inductor Selection—SEPIC Regulator

The formula below calculates the approximate inductor

value to be used for a SEPIC regulator using the LT1944.

As for the boost inductor selection, a larger or smaller

value can be used.

L

=

2

VOUT +

ILIM

VD

tOFF

Inductor Selection—Boost Regulator

The formula below calculates the appropriate inductor

value to be used for a boost regulator using the LT1944 (or

at least provides a good starting point). This value pro-

vides a good tradeoff in inductor size and system perfor-

mance. Pick a standard inductor close to this value. A

larger value can be used to slightly increase the available

output current, but limit it to around twice the value

calculated below, as too large of an inductance will in-

crease the output voltage ripple without providing much

additional output current. A smaller value can be used

(especially for systems with output voltages greater than

12V) to give a smaller physical size. Inductance can be

calculated as:

( ) VOUT − VIN MIN + VD

L=

ILIM

tOFF

where VD = 0.4V (Schottky diode voltage), ILIM = 350mA

and tOFF = 400ns; for designs with varying VIN such as

battery powered applications, use the minimum VIN value

in the above equation. For most systems with output

Current Limit Overshoot

For the constant off-time control scheme of the LT1944,

the power switch is turned off only after the 350mA current

limit is reached. There is a 100ns delay between the time

when the current limit is reached and when the switch

actually turns off. During this delay, the inductor current

exceeds the current limit by a small amount. The peak

inductor current can be calculated by:

IPEAK

=

ILIM

+

VIN(MAX)

L

−

VSAT

100ns

Where VSAT = 0.25V (switch saturation voltage). The

current overshoot will be most evident for systems with

high input voltages and for systems where smaller induc-

tor values are used. This overshoot can be beneficial as it

helps increase the amount of available output current for

smaller inductor values. This will be the peak current seen

by the inductor (and the diode) during normal operation.

For designs using small inductance values (especially at

input voltages greater than 5V), the current limit over-

shoot can be quite high. Although it is internally current

5