ICS342 Ver la hoja de datos (PDF) - Integrated Circuit Systems

Número de pieza

componentes Descripción

Fabricante

ICS342 Datasheet PDF : 7 Pages

| |||

ICS342

Field Programmable Dual Output SS VersaClock

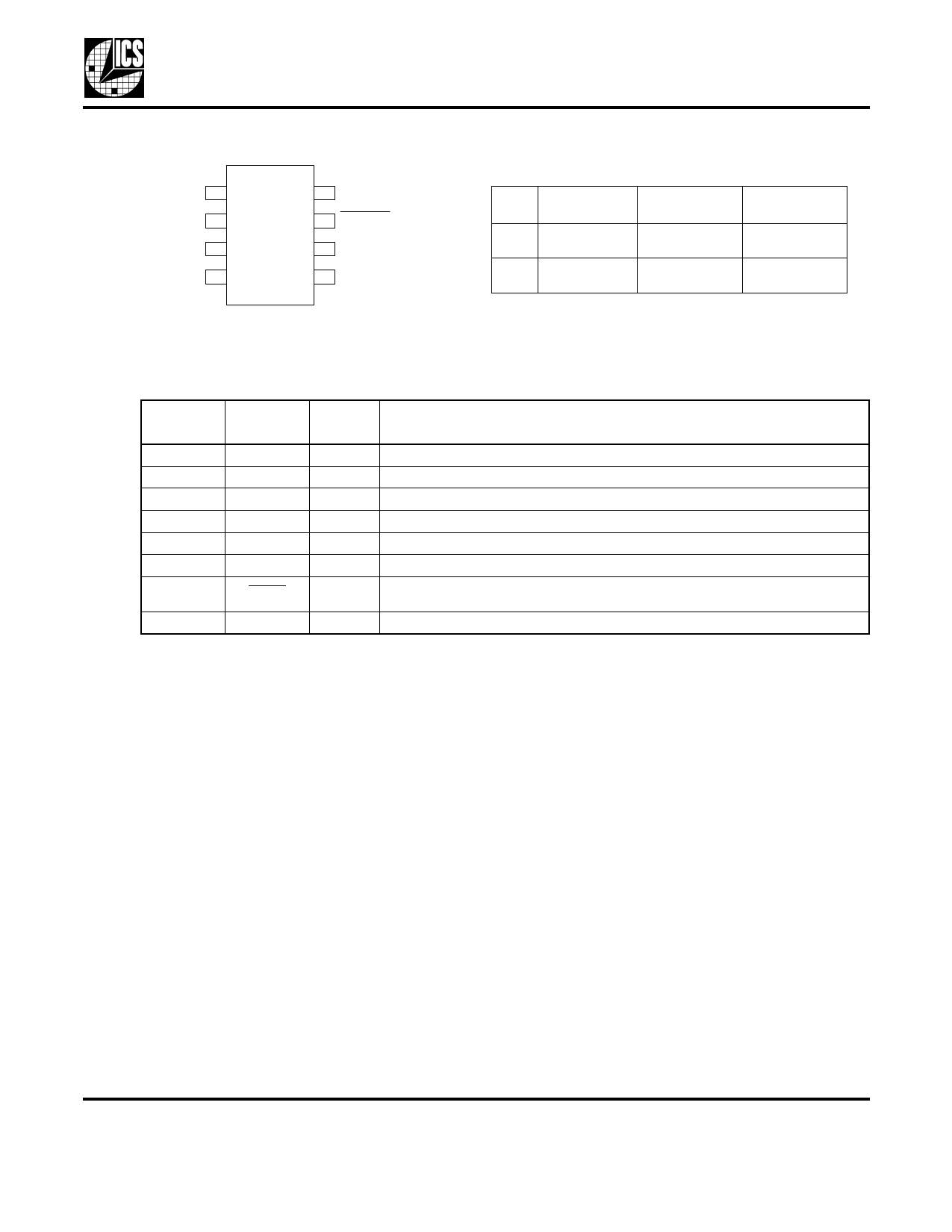

Pin Assignment

Output Clock Selection Table

X1/ICLK 1

VDD 2

GND 3

CLK1 4

8 X2

7 PDTS

6 SEL

5 CLK2

SEL CLK1 (MHz) CLK2 (MHz)

0

User

User

Configurable Configurable

1

User

User

Configurable Configurable

Spread

Percentage

User

Configurable

User

Configurable

8-pin (150 mil) SOIC

Pin Description

Pin

Number

1

2

3

4

5

6

7

8

Pin

Name

X1/ICLK

VDD

GND

CLK1

CLK2

SEL

PDTS

X2

Pin

Type

XI

Power

Power

Output

Output

Input

Input

XO

Pin Description

Connect this pin to a crystal or external clock input.

Connect to +3.3 V.

Connect to ground.

Clock output. Weak internal pull-down when tri-state.

Clock output. Weak internal pull-down when tri-state.

Select for frequency selection on CLK1 and CLK2. Internal pull-up resistor.

Powers down entire chip. Tri-states CLK outputs when low. Internal pull-up

resistor.

Connect this pin to a crystal, or float for clock input.

External Components

Series Termination Resistor

Clock output traces over one inch should use series

termination. To series terminate a 50Ω trace (a

commonly used trace impedance), place a 33Ω resistor

in series with the clock line, as close to the clock output

pin as possible. The nominal impedance of the clock

output is 20Ω.

Decoupling Capacitor

As with any high-performance mixed-signal IC, the

ICS342 must be isolated from system power supply

noise to perform optimally.

A decoupling capacitor of 0.01µF must be connected

between VDD and the PCB ground plane.

Crystal Load Capacitors

The device crystal connections should include pads for

small capacitors from X1 to ground and from X2 to

ground. These capacitors are used to adjust the stray

capacitance of the board to match the nominally

required crystal load capacitance. Because load

capacitance can only be increased in this trimming

process, it is important to keep stray capacitance to a

minimum by using very short PCB traces (and no vias)

been the crystal and device. Crystal capacitors must be

connected from each of the pins X1 and X2 to ground.

The value (in pF) of these crystal caps should equal

(CL -6 pF)*2. In this equation, CL= crystal load

capacitance in pF. Example: For a crystal with a 16 pF

load capacitance, each crystal capacitor would be 20

pF [(16-6) x 2] = 20.

PCB Layout Recommendations

For optimum device performance and lowest output

phase noise, the following guidelines should be

observed.

1) The 0.01µF decoupling capacitor should be mounted

on the component side of the board as close to the

MDS 342 F

2

Revision 090704

Integrated Circuit Systems, Inc. ● 525 Race Street, San Jose, CA 95126 ● tel (408) 297-1201 ● www.icst.com