A3969 Ver la hoja de datos (PDF) - Allegro MicroSystems

Número de pieza

componentes Descripción

Fabricante

A3969 Datasheet PDF : 9 Pages

| |||

A3969

Dual Full-Bridge PWM Motor Driver

FUNCTIONAL DESCRIPTION

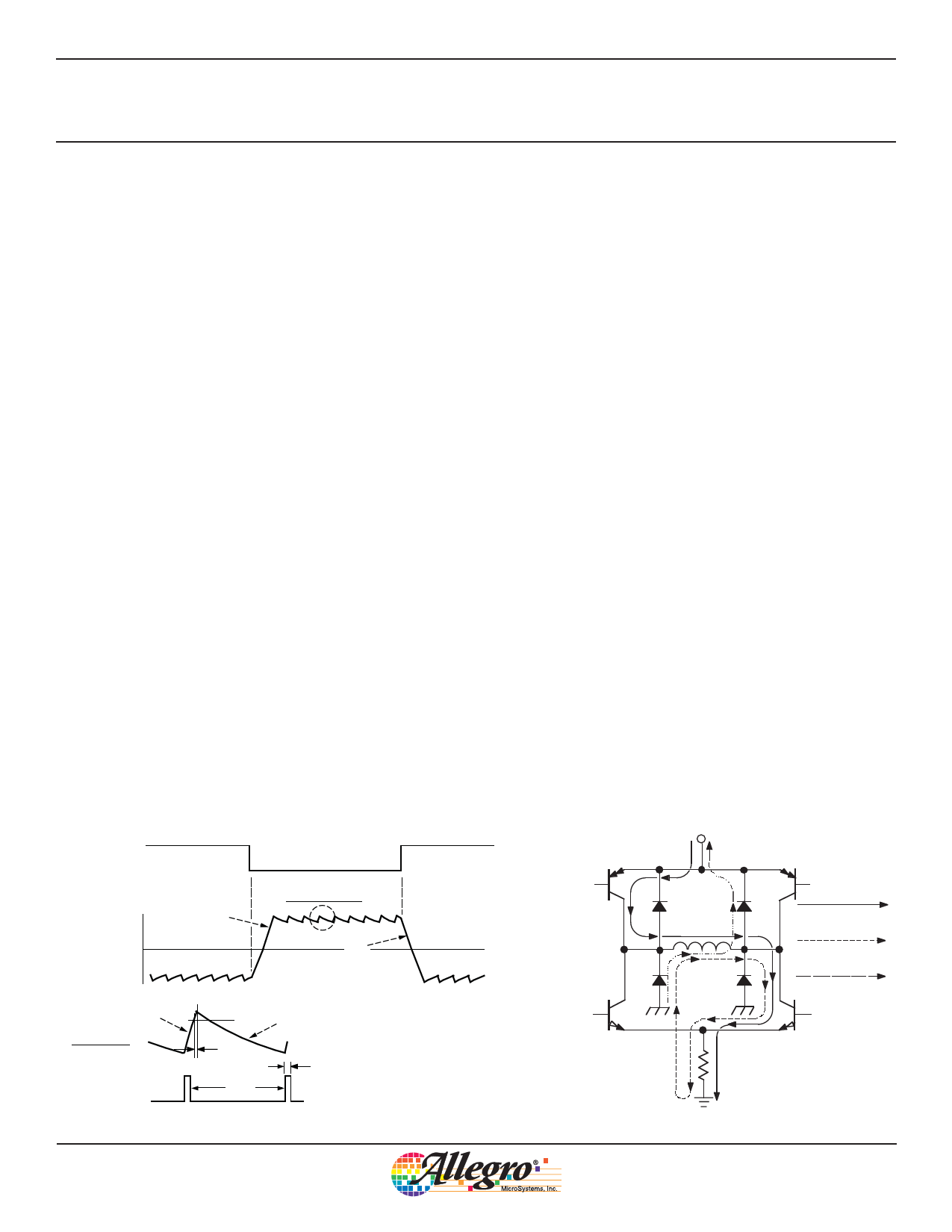

Internal PWM Current Control. The A3969 dual

H-bridge is designed to drive both windings of a bipolar

stepper motor. Load current can be controlled in each mo-

tor winding by an internal fixed-frequency PWM control

circuit. The current-control circuitry works as follows:

when the outputs of the H-bridge are turned on, current in-

creases in the motor winding. The load current is sensed by

the current-control comparator via an external sense resis-

tor (RS). Load current continues to increase until it reaches

the predetermined value, set by the selection of external

current-sensing resistors and reference input voltage (VREF)

according to the equation:

ITRIP = IOUT + ISO = VREF/(4 RS)

where ISO is the sense-current error (typically 18 mA) due

to the base-drive current of the sink driver transistor.

At the trip point, the comparator resets the source-en-

able latch, turning off the source driver of that H-bridge.

The source turn off of one H-bridge is independent of the

other H-bridge. Load inductance causes the current to

recirculate through the sink driver and ground-clamp diode.

The current decreases until the internal clock oscillator sets

the source-enable latches of both H-bridges, turning on

the source drivers of both bridges. Load current increases

again, and the cycle is repeated.

The frequency of the internal clock oscillator is set by

the external timing components RTCT. The frequency can

be approximately calculated as:

fosc = 1/(RT CT + tblank)

where tblank is defined below.

The range of recommended values for RT and CT are

20 k to 100 k and 470 pF to 1000 pF respectively.

Nominal values of 56 k and 680 pF result in a clock

frequency of 25 kHz.

Current-Sense Comparator Blanking. When the

source driver is turned on, a current spike occurs due to

the reverse-recovery currents of the clamp diodes and

switching transients related to distributed capacitance in

the load. To prevent this current spike from erroneously

resetting the source enable latch, the current-control com-

parator output is blanked for a short period of time when

the source driver is turned on. The blanking time is set by

the timing component CT according to the equation:

tblank = 1900 CT (μs).

A nominal CT value of 680 pF will give a blanking

time of 1.3 μs.

The current-control comparator is also blanked when

the H-bridge outputs are switched by the PHASE or EN-

ABLE inputs. This internally generated blank time is

approximately 1 μs.

V PHASE

+

I OUT 0

–

BRIDGE

ON

See Enlargement A

ALL

OFF

BRIDGE

ON

Enlargement A

INTERNAL

OSCILLATOR

ITRIP

td

RTCT

SOURCE

OFF

tblank

Dwg. WM-003-2

V

BB

BRIDGE ON

SOURCE OFF

ALL OFF

RS

Dwg. EP-006-16

Allegro MicroSystems, Inc.

6

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com