TCL1117 Ver la hoja de datos (PDF) - TelCom Semiconductor, Inc

Número de pieza

componentes Descripción

Fabricante

TCL1117

TCL1117 Datasheet PDF : 9 Pages

| |||

PRELIMINARY INFORMATION

TCL1117

TCL1117-2.85

TCL1117-3.30

TCL1117-5.00

800mA LOW DROPOUT POSITIVE REGULATORS

ADJUSTABLE AND FIXED 2.85V, 3.30V, 5.00V

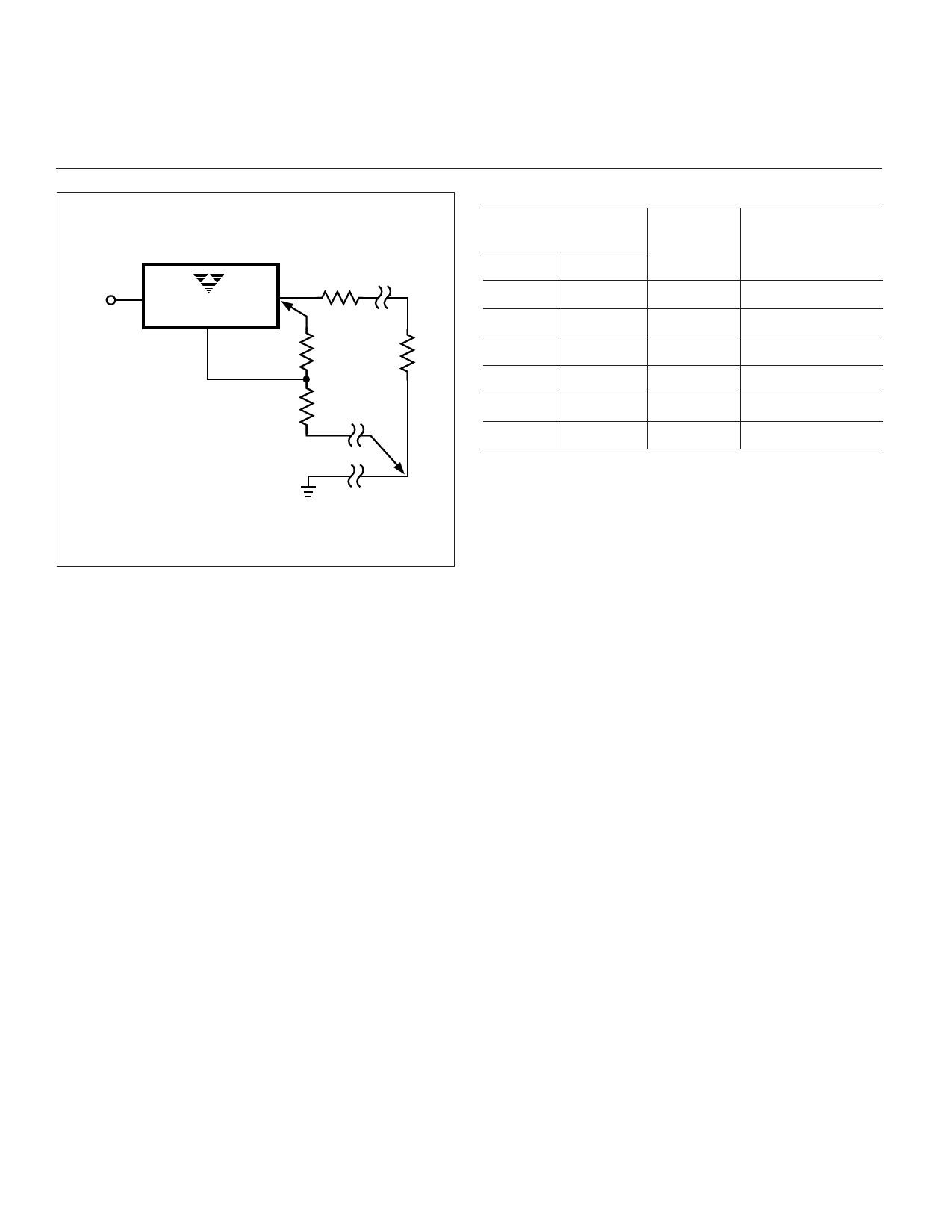

Rp

PARASITIC

LINE RESISTANCE

VIN

IN TCL1117 OUT

ADJ

R1

RL

CONNECT

R1 TO CASE

R2

Table 1.

Copper Area

Thermal

Resistance

Topside* Backside Board Area (Junction-to-Ambient)

2500 Sq. mm 2500 Sq. mm 2500 Sq. mm

45°C/W

1000 Sq. mm 2500 Sq. mm 2500 Sq. mm

45°C/W

225 Sq. mm 2500 Sq. mm 2500 Sq. mm

53°C/W

100 Sq. mm 2500 Sq. mm 2500 Sq. mm

59°C/W

1000 Sq. mm 1000 Sq. mm 1000 Sq. mm

52°C/W

1000 Sq. mm 0

1000 Sq. mm

55°C/W

*Tab of device attached to topside copper

CONNECT

R2 TO LOAD

Figure 3. Connections for Best Load Regulation

Power Dissipation and Thermal Design

As mentioned earlier, the TCL1117 has thermal over-

load protection which limits internal temperature to +165°C.

However, device functionality is only guaranteed to a maxi-

mum junction temperature of +125°C. Since internal power

dissipation can be >1 watt, careful thermal design is essen-

tial. The TCL1117 is supplied in a SOT-223 package which

is intended to be directly surface-mounted to the PC-board.

Because there is no dedicated heat sink, power dissipation

to ambient is performed largely by the PC board and its

copper material.

The power dissipation and junction temperature for the

TCL1117 in a SOT-223 are given by the following equations:

PD = (VIN – VOUT) x (IOUT)

TJUNCTION = TAMBIENT + (PD x ΘJA)

NOTE: TJUNCTION must not exceed 125°C

Soldering Methods

The recommended methods of soldering the SOT-223

package are: vapor phase re-flow and infrared re-flow with

component preheat within 65°C of the solder temperature.

Hand soldering and wave soldering methods are not recom-

mended since they can damage the part with excessive

thermal gradients across the surface area of the package.

Thermal shock to the package (>30°C per second) must be

minimized.

Ripple Rejection

Ripple Rejection curves were generated using an ad-

justable output TCL1117 with a bypass capacitor from ADJ

to ground. To obtain the performance shown in the curves,

the impedance of the bypass capacitor (at the ripple fre-

quency) should be less than R1. R1 is typically 100Ω to

200Ω. For example at 120Hz, with R1 = 100Ω, the adjust

capacitor should be at least 13µF. Only 0.16µF would be

required at 10kHz.

The output ripple increases as the ratio of the output

voltage to the reference voltage (VOUT/VREF) in fixed voltage

devices, and adjustable devices without an adjust pin ca-

pacitor. For example, at 5V, output ripple will increase by a

factor of 4 (5/1.25V). Ripple rejection will be reduced by 12db

from the value shown on the curve.

The ΘJC (junction to external tab) for the SOT-223 is

15°C/W. Depending upon heatsink parameters, the ΘCA can

be as low as 30°C/W. Therefore, the total thermal resistance

(ΘJA) is at least 45°C/W. Table 1 shows thermal resistance

measurements taken with the TCL1117 mounted on 1/16

inch 2-layer PCB with 1oz. copper foil. NOTE: The TAB pin

does not have to be soldered to all copper layers for effective

heat transfer. Use Table 1 only as a rough guide since

thermal interactions with adjacent components cannot be

predicted.

TCL1117-05 6/5/97

4