MAX3996 Ver la hoja de datos (PDF) - Maxim Integrated

Número de pieza

componentes Descripción

Fabricante

MAX3996 Datasheet PDF : 16 Pages

| |||

3.0V to 5.5V, 2.5Gbps VCSEL

and Laser Driver

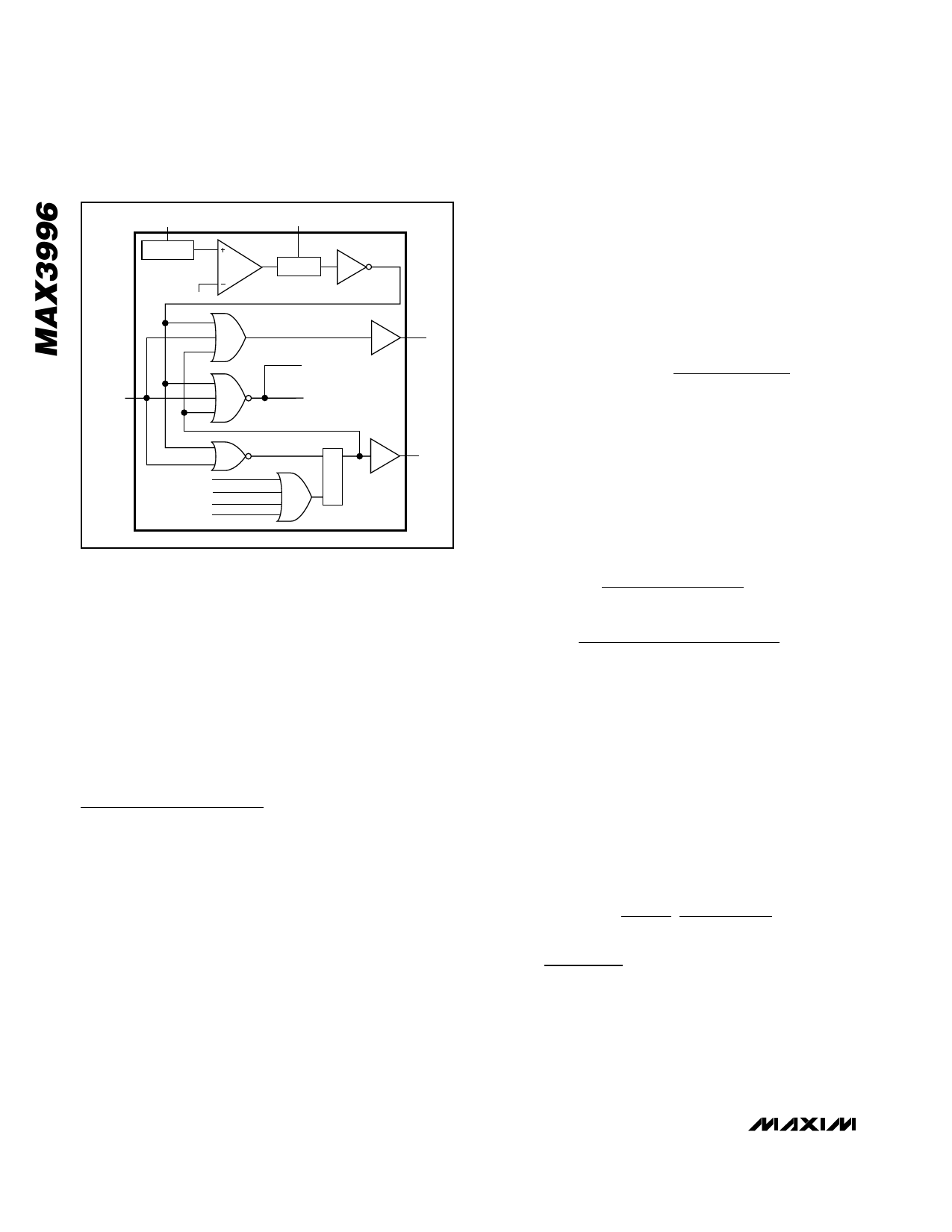

VCC

STARTUP

VBG

TX_DISABLE

BIAS FAULT 1

BIAS FAULT 2

TC FAULT

MODSET FAULT

PORDLY

DELAY

BIAS ENABLE

MODULATOR

ENABLE

FAULT LATCH

RQ

S

SHDNDRV

FAULT

Figure 7. Safety Circuitry Functional Diagram

Latched Fault Output

An open-collector FAULT output is provided with the

MAX3996. This output is latched until the power is

switched off, then on, or until TX_DISABLE is switched

to HIGH and then LOW.

Power-On Reset

The MAX3996 contains an internal power-on reset

delay to reject noise on VCC during power-on or hot-

plugging. Adding capacitance to the PORDLY pin can

extend the delay. The POR comparator includes hys-

teresis to improve noise rejection.

Design Procedure

Select Laser

Select a communications-grade laser with a rise time of

260ps or better for 1.25Gbps or 130ps or better for

2.5Gbps applications. To meet the MAX3996’s AC

specifications, the voltage at both OUT+ and OUT-

must remain above VCC - 1V at all times.

Use a high-efficiency laser that requires low modulation

current and generates a low voltage swing. Trimming

the leads can reduce laser package inductance.

Typical package leads have inductance of 25nH per

inch (1nH/mm); this inductance causes a large voltage

swing across the laser. A compensation filter network

also can be used to reduce ringing, edge speed, and

voltage swing.

Programming Modulation Current

Resistors at the MODSET and TC pins set the ampli-

tude of the modulation current. The resistor RMOD sets

the temperature-stable portion of the modulation cur-

rent, and the resistor (RTC) sets the temperature-

increasing portion of the modulation current. To

determine the appropriate temperature coefficient from

the slope efficiency (η) of the laser, use the following

equation:

( ) LASER _ TEMPCO =

η70 − η25

× 106

[ppm / °C]

η25 70°C − 25°C

For example, if a laser has a slope efficiency η25 =

0.021mW/mA, which reduces to η70 = 0.018mW/mA.

Using the above equation will produce a laser tempco

of -3175ppm/°C.

To obtain the desired modulation current and tempco

for the device, the following equations can be used to

determine the required values of RMOD and RTC:

R TC

=

0.22

Tempco /106

×

iMOD

−

250Ω

( ) RMOD

=

Tempco /106

0.19 − 48 ×

RTC + 250Ω 52

Tempco

/

106

−

250Ω

where tempco = -laser tempco, 0 < tempco <

4000ppm/°C, and 2mA < iMOD < 30mA.

Figure 8 shows a family of curves derived from these

equations. The straight diagonal lines depict constant

tempcos. The curved lines represent constant modula-

tion currents. If no temperature compensation is

desired, leave TC open, and the equation for iMOD-

simplifies considerably.

The following equations were used to derive Figure 8 and

the equations at the beginning of this section.

iMOD

=

77 ×

50

50 + RL

1.15

RMOD + 250Ω

+

1.06

RTC + 250Ω

(1

+

0.004(T

−

25°C))Amps

10 ______________________________________________________________________________________