MAX785 Ver la hoja de datos (PDF) - Maxim Integrated

Número de pieza

componentes Descripción

Fabricante

MAX785 Datasheet PDF : 24 Pages

| |||

Product Reliability Report

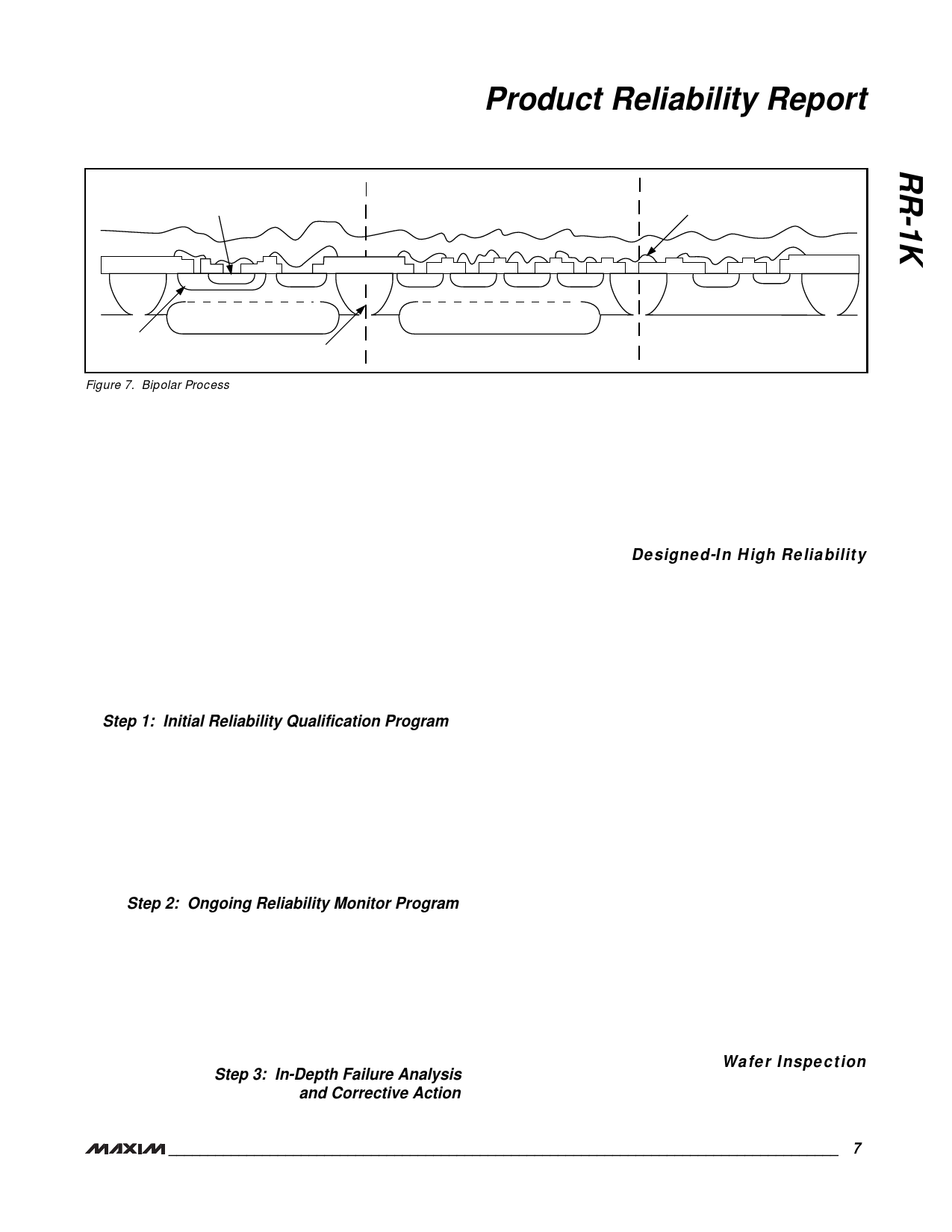

NPN

LATERAL PNP

VERTICAL PNP

N+ EMITTER = 2.5µm

Al/Si (1%) = 11kÅ

,,,,,,,,,,,,,, ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, SiO2/Si3N4=0.8µm

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

P+ ISO

,,,,P,+ ,,,,,,N,+,,,,,,,,,,,,N,+,,,,,,,

P+ ISO

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,P,+,,,,,,,,,P,+,,,,,,,,,P,+,,,,,,,,,,N,+,,,,,,,,P,+,,I,SO,,,,,,,,,,,,P,+,,,,,,,,,,N,+,,,,,,, P+ ISO

N EPI = 17µm

N+ BURIED LAYER = 4.5µm

N+ BURIED LAYER = 4.5µm

P BASE = 3µm

P+ ISOLATION = 20µm

P SUBSTRATE <111>

Figure 7. Bipolar Process

manufacturing steps must be subjected to Maxim’s

reliability testing before release to manufacturing for

mass production. Our reliability program includes

the following steps:

Step 1: Initial Reliability Qualification Program

Step 2: Ongoing Reliability Monitor Program

Step 3: In-Depth Failure Analysis and

Corrective Action

Tables 5–11 show the results of long-term Life Tests

by process and device type. Tables 12–16 show

the results of the 85/85, Pressure Pot, HAST,

Temperature Cycling, and High-Temperature

Storage Life tests, by device type. Tables 17 and

18 show hybrid product reliability.

Step 1: Initial Reliability Qualification Program

Maxim’s product reliability test program meets EIA-

JEDEC standards and most standard OEM reliabili-

ty test requirements.

Table 1 summarizes the qualification tests that are

part of Maxim’s reliability program. Before releasing

products, we require that three consecutive manu-

facturing lots from a new process technology suc-

cessfully meet the reliability test requirements.

Step 2: Ongoing Reliability Monitor Program

Each week Maxim identifies three wafer lots per

process per fab to be the subjects of reliability moni-

tor testing. Each lot is Pressure Pot tested, and tested

to 192 hours of High-Temperature Life (at 135°C). On

a quarterly basis, one wafer lot per process per fab is

identified and subjected to the same long-term relia-

bility tests as defined in Table 1. Test results are fed

back into production.

Step 3: In-Depth Failure Analysis

and Corrective Action

Our technical failure-analysis staff is capable of ana-

lyzing every reliability test failure to the device level. If

an alarming reliability failure mechanism or trend is

identified, the corrective action is initiated automati-

cally. This proactive response and feedback ensures

that discrepancies in any device failure mechanism

are corrected before becoming major problems.

Designed-In High Reliability

A disciplined design methodology is an essential

ingredient of manufacturing a reliable part. No

amount of finished-product testing can create relia-

bility in a marginal design.

To design-in reliability, Maxim began by formulating a

set of physical layout rules that yield reliable products

even under worst-case manufacturing tolerances.

These rules are rigorously enforced, and every circuit

is subjected to computerized Design Rule Checks

(DRCs) to ensure compliance.

Special attention is paid to Electrostatic Discharge

(ESD) protection. Maxim’s goal is to design every

pin of every product to withstand ESD voltages in

excess of 2000V, through a unique protection struc-

ture. In the case of our RS-232 interface circuits,

products can even withstand ±15kV ESD using the

human-body model, ±8kV ESD using IEC1000-4-2

contact discharge, or ±15kV ESD using IEC1000-4-2

air-gap discharge. Maxim tests each new product

for designed 50mA latchup protection.

Designs are extensively simulated (using both

circuit and logic simulation software) to evaluate

performance under worst-case conditions.

Finally, every design is checked and rechecked

by independent teams before being released to

mask making.

Wafer Inspection

All wafers are fabricated using stable, proven

______________________________________________________________________________________ 7