LT3465A Ver la hoja de datos (PDF) - Linear Technology

Número de pieza

componentes Descripción

Fabricante

LT3465A Datasheet PDF : 12 Pages

| |||

LT3465A

APPLICATIO S I FOR ATIO

Table 3 gives inrush peak currents for some component

selections.

Table 3. Inrush Peak Current

VIN (V)

5

r (Ω)

0.5

5

0.5

3.6

0.5

5

0.5

L (µH)

22

22

22

33

C (µF)

0.22

1

0.22

1

IP (A)

0.38

0.70

0.26

0.60

LED Current and Dimming Control

The LED current is controlled by the feedback resistor (R1

in Figure 1) and the feedback reference voltage.

ILED = VFB/RFB

The CTRL pin sets the feedback reference voltage as

shown in the Typical Performance Characteristics. When

CTRL is at 1.8V or more, the feedback reference is 200mV,

which results in full-scale LED current. The CTRL pin can

be used as a dimming control when its voltage is between

200mV to 1.5V. To maintain LED current accuracy, a 1%

or better resistor for R1 is recommended. The formula and

table for RFB selection are shown below:

RFB = 200mV/ILEDF

where ILEDF is full-scale LED current

Table 4. RFB Resistor Value Selection

ILED (mA)

5

10

15

20

R1 (Ω)

40.2

20.0

13.3

10.0

Dimming Using Filtered PWM

Dimming can be realized by using an RC filter in front of the

CTRL pin to filter a PWM signal, as depicted in Figure 5.

The filtered PWM signal is equivalent to a constant volt-

age. The time constant R1 • C1 should be much lower than

the frequency of the PWM signal. Additionally, R1 should

be small compared to the 50kΩ impedance of the CTRL

pin. Suggested values are shown in Figure 5.

R1

5k

PWM

LT3465

CTRL

C1

100nF

3465 F06

Figure 5. Dimming Control Using a Filtered PWM Signal

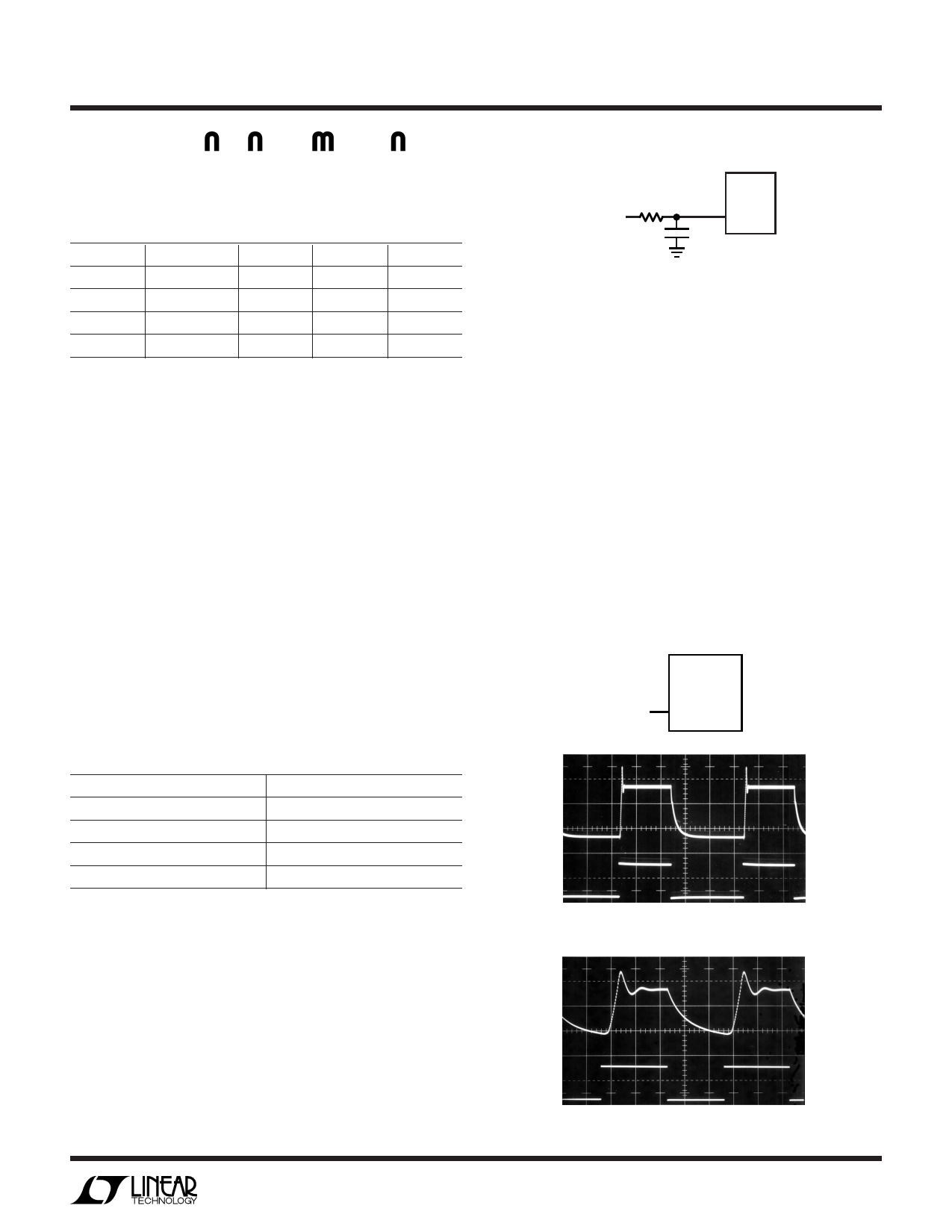

Dimming Using Direct PWM

Unlike the LT3465, the LT3465A does not have internal

soft-start. Although the input current is higher during

start-up, the absence of soft-start allows the CTRL pin to

be directly driven with a PWM signal for dimming. A zero

percent duty cycle sets the LED current to zero, while

100% duty cycle sets it to full current. Average LED current

increases proportionally with the duty cycle of the PWM

signal. PWM frequency should be between 1kHz and

10kHz for best performance. The PWM signal should be at

least 1.8V in magnitude; lower voltage will lower the

feedback voltage as shown in Equation 1. Waveforms are

shown for a 1kHz PWM and 10kHz PWM signal in Figures

6a and 6b respectively.

PWM

LT3465A

CTRL

FB

100mV/DIV

CTRL

2V/DIV

FB

100mV/DIV

CTRL

2V/DIV

200µs/DIV (1kHz)

Figure 6a.

3465A F06a

20µs/DIV (10kHz)

Figure 6b.

3465A F06b

3465ai

7