HIP6521(2000) Ver la hoja de datos (PDF) - Intersil

Número de pieza

componentes Descripción

Fabricante

HIP6521 Datasheet PDF : 13 Pages

| |||

HIP6521

equally large amounts of noise. The critical small signal

components are those connected to sensitive nodes or

those supplying critical bypass current.

The power components and the controller IC should be

placed first. Locate the input capacitors, especially the high-

frequency ceramic decoupling capacitors, close to the power

switches. Locate the output inductor and output capacitors

between the MOSFETs and the load. Locate the PWM

controller close to the MOSFETs.

+5VIN

LIN

+

CIN

VOUT2

+

COUT2

+12V

CVCC

VCC GND

OCSET

COCSET

ROCSET

UGATE

PHASE

Q1

LOUT

VOUT1

DRIVE2

Q3

LGATE

Q2

COUT1+

CR1

VOUT3

+

COUT3

Q4

HIP6521

VOUT4

DRIVE3 DRIVE4

+

COUT4

PGND

Q5

+3.3VIN

KEY

ISLAND ON POWER PLANE LAYER

ISLAND ON CIRCUIT OR POWER PLANE LAYER

VIA CONNECTION TO GROUND PLANE

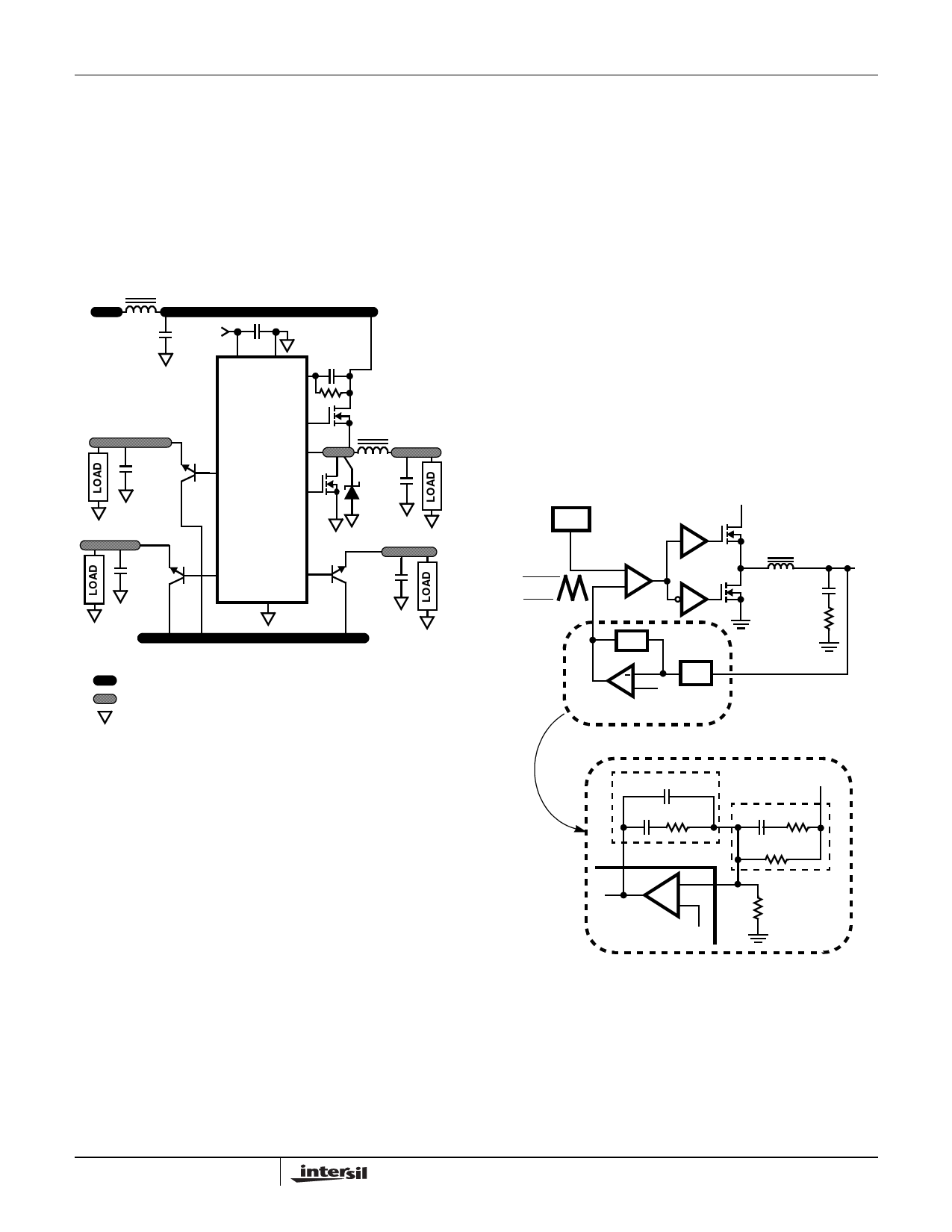

FIGURE 5. PRINTED CIRCUIT BOARD POWER PLANES AND

ISLANDS

The critical small signal components include the bypass

capacitor for VCC and the feedback resistors. Locate these

components close to their connecting pins on the control IC.

A multi-layer printed circuit board is recommended. Figure

5 shows the connections of the critical components in the

converter. Note that the capacitors CIN and COUT each

represent numerous physical capacitors. Dedicate one

solid layer for a ground plane and make all critical

component ground connections with vias to this layer.

Dedicate another solid layer as a power plane and break

this plane into smaller islands of common voltage levels.

The power plane should support the input power and

output power nodes. Use copper filled polygons on the top

and bottom circuit layers for the PHASE nodes, but do not

unnecessarily oversize these particular islands. Since the

PHASE nodes are subjected to very high dV/dt voltages,

the stray capacitor formed between these islands and the

surrounding circuitry will tend to couple switching noise.

Use the remaining printed circuit layers for small signal

wiring. The wiring traces from the control IC to the

MOSFET gate and source should be sized to carry 2A

peak currents.

PWM Controller Feedback Compensation

The PWM controller uses voltage-mode control for output

regulation. This section highlights the design consideration

for a PWM voltage-mode controller. Apply the methods and

considerations only to the PWM controller.

Figure 6 highlights the voltage-mode control loop for a

synchronous-rectified buck converter. The output voltage

(VOUT) is regulated to the Reference voltage level, 0.8V. The

error amplifier (Error Amp) output (VE/A) is compared with

the oscillator (OSC) triangular wave to provide a pulse-width

modulated (PWM) wave with an amplitude of VIN at the

PHASE node. The PWM wave is smoothed by the output

filter (LO and CO).

VIN

OSC

DRIVER1

∆VOSC

PWM

COMP

-

+

SYNC

DRIVER

LO

PHASE

VOUT

CO +

ESR

(PARASITIC)

ZFB

VE/A

+

ERROR

AMP

ZIN

0.8V

DETAILED COMPENSATION COMPONENTS

C2

C1 R2

ZFB

VOUT

ZIN

C3 R3

COMP

RS1

FB

-

+

RP1

HIP6521

0.8V

FIGURE 6. VOLTAGE-MODE BUCK CONVERTER

COMPENSATION DESIGN

The modulator transfer function is the small-signal transfer

function of VOUT/VE/A. This function is dominated by a DC

Gain, given by VIN/VOSC, and shaped by the output filter,

with a double pole break frequency at FLC and a zero at

FESR .

8