AD9984AKSTZ-170 Ver la hoja de datos (PDF) - Analog Devices

Número de pieza

componentes Descripción

Fabricante

AD9984AKSTZ-170 Datasheet PDF : 44 Pages

| |||

AD9984A

Negative target codes are included to duplicate a feature that is

present with manual offset adjustment. The benefit that is

mimicked is the ability to easily adjust brightness on a display. By

setting the target code to a value that does not correspond to the

ideal ADC range, the end result is an image that is brighter or

darker. A target code higher than ideal results in a brighter image,

whereas a target code lower than ideal results in a darker image.

The ability to program a target code offers a large degree of

freedom and flexibility. Although all channels are set to either 1

or 512 in most cases, the flexibility to select other values makes

it possible to insert intentional skews between channels. It also

allows the ADC range to be skewed so that voltages outside of

the normal range can be digitized. For example, setting the

target code to 40 allows the sync tip, which is normally below

black level, to be digitized and evaluated.

The internal logic for the auto-offset circuit requires 16 data

clock cycles to perform its function. This operation is executed

immediately after the clamping pulse. Therefore, it is important

to end the clamping pulse signal at least 16 data clock cycles

before active video. This is true whether using the AD9984A

internal clamp circuit or an external CLAMP signal. The auto-

offset function can be programmed to run continuously or on a

one-time basis (see the 0x2C—Bit[4] Auto-Offset Hold

section). In continuous mode, the update frequency can be

programmed (Register 0x1B, Bits[4:3]). Continuous operation

with updates every 192 Hsyncs is recommended.

Guidelines for basic auto-offset operation are shown in Table 6

and Table 7.

Table 6. RGB Auto-Offset Register Settings

Register

Value Comments

0x0B

0x00 Sets red target to 4.

0x0C

0x80 Must be written.

0x0D

0x00 Sets green target to 4.

0x0E

0x80 Must be written.

0x0F

0x00 Sets blue target to 4.

0x10

0x80 Must be written.

0x18, Bits[3:1] 000

Sets red, green, and blue channels to

ground clamp.

0x1B, Bits[5:3] 110

Selects update rate to every 192

clamps and enables auto-offset.

Table 7. YPbPr Auto-Offset Register Settings

Register

Value Comments

0x0B

0x40 Sets Pr (red) target to 512.

0x0C

0x00 Must be written.

0x0D

0x00 Sets Y (green) target to 4.

0x0E

0x80 Must be written.

0x0F

0x40 Sets Pb (blue) target to 512.

0x10

0x00 Must be written.

0x18, Bits[3:1] 101

Sets Pb, Pr to midscale clamp and Y to

ground clamp.

0x1B, Bits[5:3] 110

Selects update rate to every 192

clamps and enables auto-offset.

Automatic Gain Matching

The AD9984A includes circuitry to match the gains between

the three channels to within 1% of each other. Matching the

gains of each channel is necessary to achieve good color balance

on a display. On products without this feature, gain matching is

achieved by writing software that evaluates the output of each

channel, calculates gain mismatches, and then writes values to

the gain registers of each channel to compensate. With the auto

gain matching function, this software routine is no longer needed.

To activate auto gain matching, set Register 0x3C, Bits[2:0] to 110.

Auto gain matching has similar timing requirements to auto

offset. It requires 16 data clock cycles to perform its function,

starting immediately after the end of the clamp pulse. Unlike

auto offset, auto gain matching does not require that these

16 clock cycles occur during the back porch reference time,

although it is recommended. During auto gain matching

operation, the data outputs of the AD9984A are frozen (held at

the value they had just prior to operation). The auto gain

matching function can be programmed to run continuously or

on a one-time basis (see the 0x3C—Bit[3] Auto Gain Matching

Hold section). In continuous mode, the update frequency can

be programmed (Register 0x1B, Bits[4:3]). Continuous

operation with updates every 192 Hsyncs is recommended.

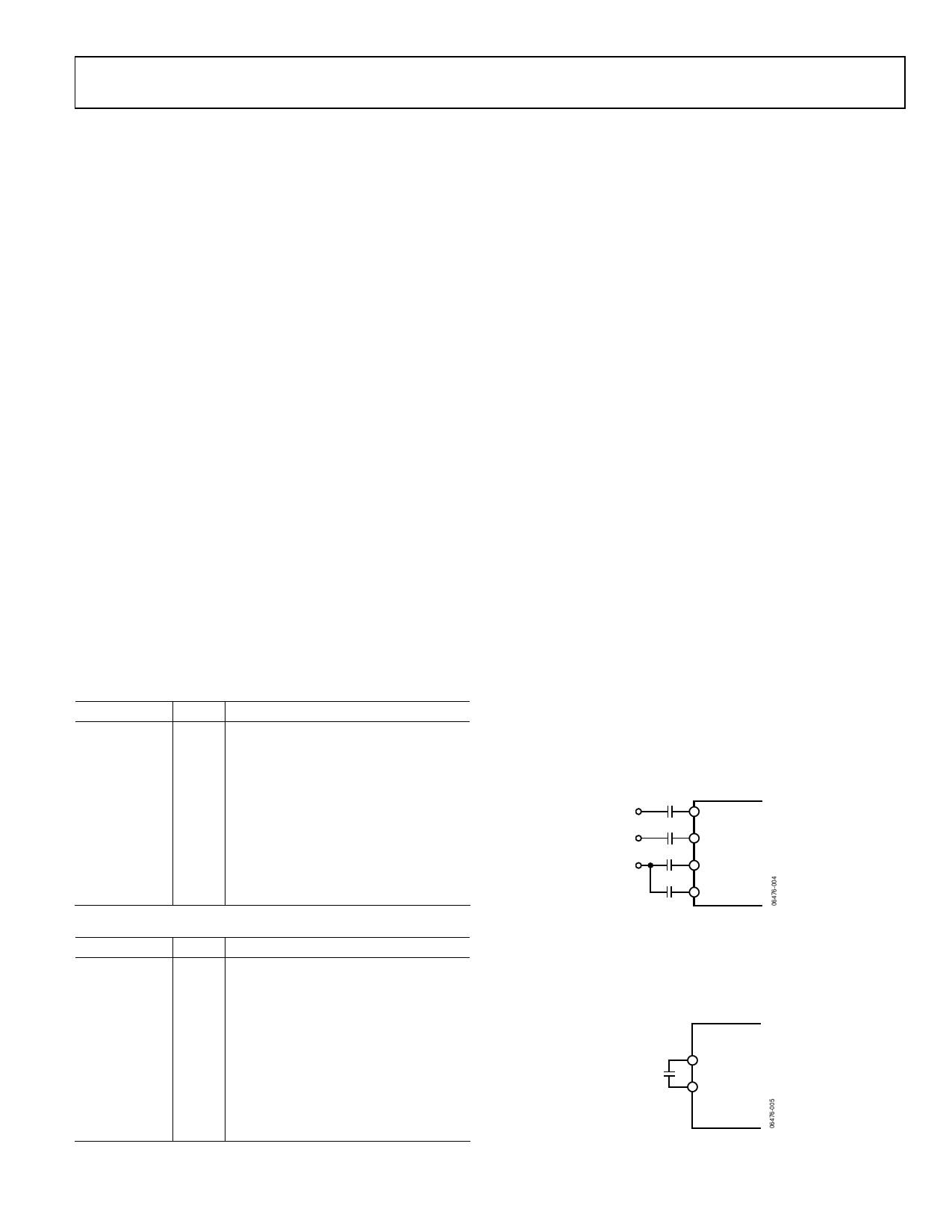

SYNC-ON-GREEN

The sync-on-green inputs (SOGIN0, SOGIN1) operate in two

steps. First, they set a baseline clamp level off the incoming

video signal with a negative peak detector. Second, they set the

voltage level of the SOG slicer’s comparator (Register 0x1D,

Bits[7:3]) with a variable trigger level to a programmable level

(typically 128 mV) above the negative peak. Each sync-on-

green input must be ac-coupled to the green analog input

through its own capacitor. The value of the capacitor must be

1 nF ± 20%. If sync-on-green is not used, this connection is not

required. The sync-on-green signal always has negative polarity.

47nF

47nF

47nF

1nF

RAIN

BAIN

GAIN

SOGIN

Figure 5. Typical Input Configuration

REFERENCE BYPASSING

REFLO and REFHI are connected to each other by a 10 μF

capacitor (see Figure 6). These references are used by the input

ADC circuitry.

10µF

REFHI

REFLO

Figure 6. Input Amplifier Reference Capacitors

Rev. 0 | Page 13 of 44